Controlled impedance & Integrity

Controlled Impedance

The increase in the signal speed enabled by modern electronic components has forced laminate manufacturers to design and manufacture special materials, capable of ensuring certain and stable behaviour as the operating frequency progresses, while preserving signal integrity.

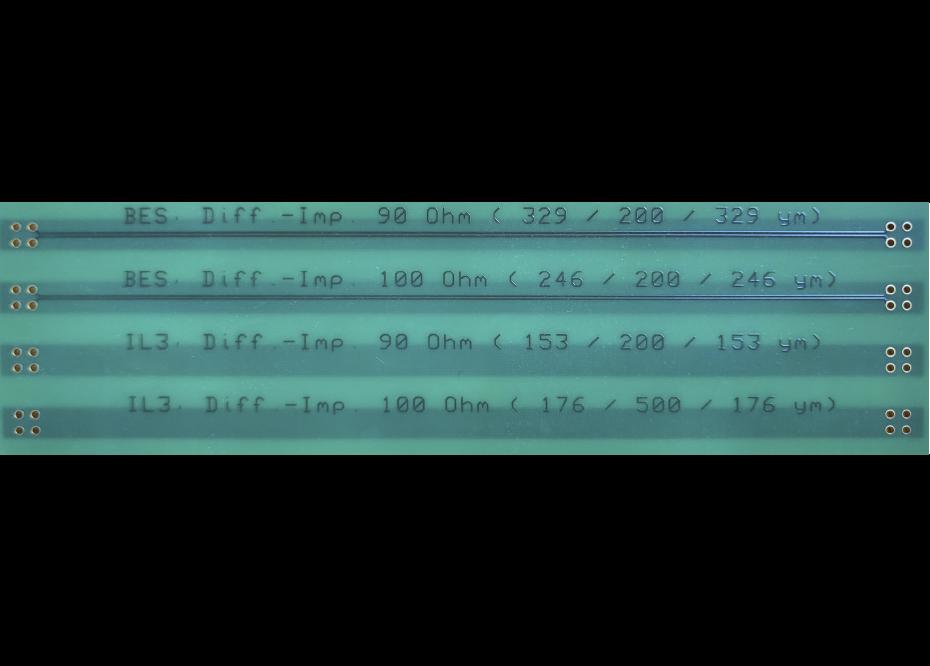

At the same time, PCB manufacturers have improved their manufacturing process by ensuring that tolerances are progressively narrower and reproducibility is achieved on an industrial scale.

The production cycle of the first batch of each new controlled-impedance printed circuit board has a specific control plan for both the inner layer production process and the pressing process.

The validation of these processes consists in checking the thickness of dielectrics by means of measurements on metallographic sections taken at specific points.

We support you in calculating the correct layup based on your chosen design and material, and in selecting alternative materials to ensure the best performance of your controlled-impedance PCBs.